- We listen to all your inquiries

- 0500086605

- info@smartskill.sa

Engineering Management

Engineering Management

The Engineering Department consists of a team with experience in designing and studying metal structures and pre-engineered buildings, each building

Customer Requirements (PEB). It is studied and designed according to the latest international and local codes, in a manner that suits the nature of each project

And consultants to ensure the safety of the facility.

Computer software is used professionally by engineers

To conduct accurate 3D analysis, design and detail of each building with

Meet the highest industry standards in design code applications

Approval drawings and manufacturing drawings in high precision.

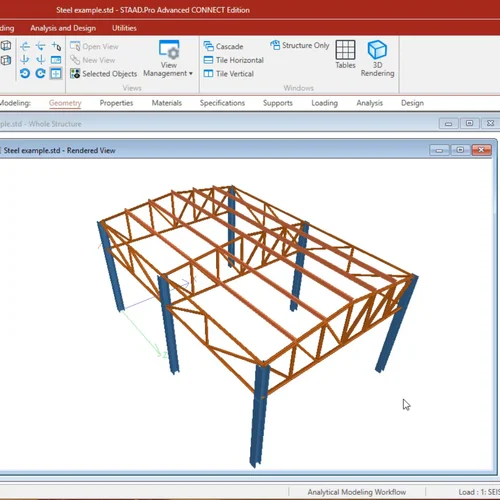

Design Software

SAP programs are professional structural analysis and design programs, allowing

For engineers to study the condition of the building,

On a real 3D model and work to examine the internal stresses generated by the applied loads, on

For example: static and moving loads and cranes, with the addition of natural forces resulting from winds and earthquakes.

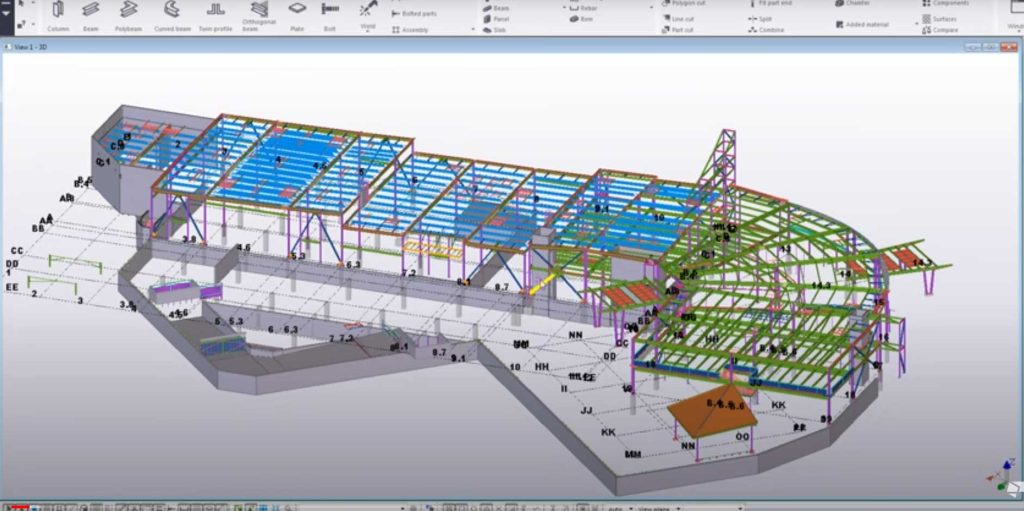

Construction detail programs

Tekla Structures is considered

Complete 3D, on which all workshop drawings are automatically created and sent to the factory for manufacturing

Steel sections are carefully selected according to American Society for Testing and Materials, or equivalent other known standards, for example, physical JIS–EN, etc. All materials must meet appropriate chemical specifications that are compatible with building manufacturing:

• ASTM A572 Grade 50

(Steel Plates and Hot Rolled Sections…etc)

ألواح معدنية وأقسام الصلب المدرفل على الساخن

• ASTM Grade 36

(Anchor Bolts, Rods…etc)

براغي وقُضبان تثبيت … إلخ

• ASTM A653 G90

(Cold-Formed Z and C sections)

القطاعات الثانوية المشكلة على البارد

• ASTM A755, ASTM A924

(Sheeting and Deck)

ألواح وأرضيات

• ASTM A475

(Cables)

كابلات

• ASTM A325

(Bolts)

براغي

• ASTM A563

(Nuts)

صواميل

• ASTM A436, 8s or 10s

(Washers)

وردات

When the iron caliber is determined by the consultant, intelligent skill ensures that the appropriate materials are purchased in accordance with the highest standards and specifications that are applied

Minimum facility codes

Smart Skill is committed to using global load codes, taking into account local codes required by some official bodies and some consulting offices:</p

International Construction Code IBC 2006 (ICC)</p

American Society of Civil Engineers ASCE7

Saudi Building Code SBC

Design codes:

American Institute of Metal Construction AISC2 005,360

American Iron and Steel Institute, AISI 2007

British Standards Institute, BS 5950

European Code 3 for the design of concrete and metal structures, EN 1-3, 2006

American Society of Civil Engineers ASCE7

American Welding Association, 2006 AWS D1.1

Manuals and design guides

Metal Fabrication Manufacturers Association (2006 MBMA)

American Institute of Metallurgical Construction Design Manual (AISC, DG09)

American Institute of Metallurgical Construction Design Manual (AISC, DG07)

Engineering team production

The Engineering Department prepares all necessary documents for approval, manufacturing, and installation. Once the customer requests it, some documents are submitted to the customer in paper or electronic form.

List of documents being prepared

Accounts note

Accreditation drawings

Airline installation diagrams

Installation drawings

Workshop details: Apply to the Smart Skill factory